Technical Data

Ponderosa pine (Pinus ponderosa) wood block flooring.

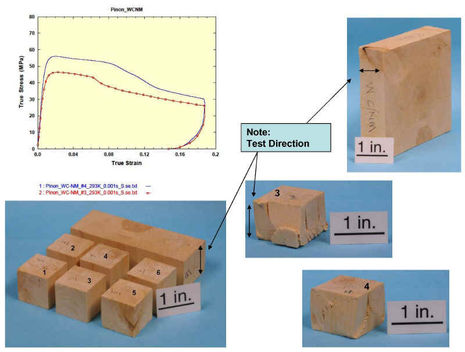

Quality wood block flooring begins with selecting the right tree species. Requirements include durability (particularly compression parallel to the grain) and the ability of the wood to hold its shape and size. But what are the specifics on minimum durability and maximum shrinkage? Unfortunately, the science for wood blocks just hasn’t been tested. The Handbook of Wood (2010), the authority on properties and mechanics of wood, offers a suite of information on wood strengths and shrinkage, but how does this apply to wood block flooring?

Wood is known as an orthotropic material or it has unique and independent mechanical properties in the directions of three mutually perpendicular axes: longitudinal, radial, and tangential. In the case of wood flooring, these properties determine not only the strength of the wood, but also how the wood shrinks and deforms with increases and decreases of moisture content.

Durability

Addressing the issue of durability of wood block floors requires an understanding of the function of the floor itself. One setting that best presents the need for durability is in factory flooring. Factory floors are frequently required to withstand pressures of 15,000 lbs or more. This weight is based on average maximum loadings across a range fork-lift models and using average surface areas of both three and four wheel fork-lift’s results in a mean of 75 psi when converted. According to The Handbook of Wood ponderosa pine can withstand weights 2,450 psi (green) and 5,320 psi (12% moisture). Also important to note is that these numbers represent an average for the species and standard deviations are not reported. Soft wood tree species, such as ponderosa pine, will fall above and below these figures dependant on growth rate. Increases in growth rates usually result in decreased specific gravity and lower mechanical strength. This extremely important in areas of the southwest U.S. where ponderosa pine forests are notoriously dense and growth rates are extremely slow.

Another factor affecting the durability of wood is the presence of knots. There are two main types of knots (inter-grown and encased) that affect durability. Inter-grown knots have more of an effect on durability, given that it is caused by a living branch that continues to grow along with the tree and thus causing a greater disruption of continuous grain. Encased knots are caused by dead branches, which are no longer growing and cease to cause a disruption of continuous grain. Ponderosa pine is well known for its small encased knots compared to other pines used in flooring and in particular, the ponderosa pine of the Southwest has fewer and smaller encased knots because of dense growing conditions.

Finally, the presence of pitch pockets in wood will also decrease the durability of wood blocks. Again, arid, competitive environments of the Southwest result in less pitch production and fewer pitch pockets in ponderosa pine.

Shrinkage and deformations

Equally as important as durability is the ability of a wood block to hold its size and shape. Wood will not only shrink and warp during kiln drying, but also between seasons and fluctuating humidity levels. Under changing moisture conditions wood block floors can experience gap formations and become disjointed. This phenomenon expresses the need for the use of woods that have smaller fluctuations in shape and size with differing moisture conditions. Of the most popular soft wood block flooring species, ponderosa pine experiences the least amount of shrinkage and deformation of the commonly used soft wood species (Table 1).

Table 1. Percent loss (shrinkage) from green to 12% moisture for popular wood flooring soft wood species.

Species Radial (%) Tangential (%)

Longleaf pine 5.1 7.5

Loblolly pine 4.8 7.4

Slash pine 5.4 7.6

Pond pine 5.1 7.1

Ponderosa pine 3.9 6.2

Past management and climactic conditions across the southwest United States have resulted in slow growing, dense ponderosa pine forests. This has also resulted in a high percentage of stems being in low diameter classes. These small diameter stems are ideal for wood block production, given their abundance and the need for wood market development in the Southwest. The benefits of ponderosa pine as a reliable, durable wood block material are supported by current literature. Add in the fact that ponderosa pine is the preferred soft wood species aesthetically and a strong case is made for ponderosa pine as an elite wood block flooring material.

Tribal Wall Panels

Handle somewhat carefully!

As the name implies, there are Tribal origins to this product. Actually, these lovely wall panels are part of a very much larger goal of scientific, well done, triple bottom line forestry and wild land management. Originally made of Salt Cedar harvested from the Galisteo Arroyo by Kewa forestry crews doing aquifer management work, removing the non-native species of Russian Olive and Salt Cedar in an effort to restore water flow to the arroyo. From there, we’ve expanded to Single Seed Juniper, salvaged from arroyos, fence lines and science mandated thinning efforts, often on Tribal lands. The making of these panels, the forestry behind them and Old Woods overall efforts have been funded by the US Forest Service Collaborative Forest Restoration Program (CFRP), the Wood Innovations Grant of the Forest Products Lab, WERC and the Value Added Producer Program of the USDA (VAPG). Each of these programs shares Old Woods goals of creating value added products from well sourced wood products to support the goals of scientific, collaborative, Tribal and community based efforts. We do a good job in the woods and in our plant, creating jobs for the folks who live in and around the forests so they “won’t have to eat the elephants” but can make a living doing noble work. We’ve worked with Ohkay Owingeh, Jemez, Alamo Navajo, Ramah Navajo, White Mountain Apache and nearly all the local mills in Colorado, NM and Arizona in our work making beautiful floors, walls and architectural features which all contribute to these very lofty goals. This is the real deal, not green-wash! Thanks for helping us do a good job!

Installation and up-fitting your panels: depending on the size and shape, your panels will most likely come on a custom made pallet, well packed in cardboard etc. Be sure to reclaim or reuse the packing materials as you are able. Carefully cut any banding using a sharp knife or cutters. Watch your eyes when doing this, these bands can snap dangerously open.

*Assess your installation; be sure you know which panel will go where.

*The rounds are usually laid to the edge but not over it for installation reasons. This is so they will go up cleanly and butt up to each other without breaking or overlapping blocks.

*You have been provided with spare blocks and probably the glue needed to make the panels appear seamless once installed. Take a look at those and be thinking how you will use them.

*Trimming: If you need to size the panels to fit, we recommend a fine toothed joinery blade on a table saw. 80 would be appropriate. Be sure to keep the blade up high enough that the descending tooth is pressing the panel into the saw table, not trying to kick back at you. Follow all instructions and safety precautions such as eye protection and don’t do this without supervision or previous knowledge of the process of running a table saw.

*Repair, replace, adjust: use the blocks and glue provided to cover gaps, replace broken or missing blocks.

*Finishing: if you plan to finish the panels, use a simple sprayer method (simple but good hand spray bottles work usually) to apply Old Wood House Oil Blend or other thin oil finish.

Old Wood House Oil Blend has a lemony aroma and can be thinned to suit very easily.

Be careful not to make them sticky with too much oil. They are already a bit challenging to keep clean. See cleaning instructions below!

You may opt to spray them with a water based polyurethane. If so, consider cutting the product with clean water to make it spray more easily. Call us if you have questions.

*Drill and screw: drill holes appropriate for the screws to be used or alternately mount any plate or bracket type hardware to be used in mounting the panels. If mounting with wood screws, drill your holes, as possible, in gaps between the blocks. You’ll never see them again. They’ll be hidden.

Six or eight screws ought to be adequate but you are responsible so do a good job!

*Cover Up time! Get your favorite politician mask out…JK! After the panels are mounted, you can get creative yourself and use the provided blocks and glue to cover the lines between panels, expand the edges to give a more ‘wild look’ or just have fun. Don’t go overboard; less is more with these things. The eye wanders around but seldom settles and nobody is looking for perfection on these. You can build castles and strange alien landscapes; remember, less is more.

*Cleaning: a vacuum cleaner with that brush thingy attachment that your Mom used on the venetian blinds. That or swap the hose around and use the shop vac as a blower. You can also use a soft ‘butler brush’ to keep them tidy looking. Repair any missing blocks as you do this.

If you catch your least favorite nephew breaking blocks off the wall, … let his little sister do the repair; that way she’ll have all the fun. Seriously, a hot glue gun is handy for repair work as it sets rapidly so you won’t have freshly glued blocks falling off the wall right after you let go.